Based on the requirements of our customers, we also provide machining of produced forgings as the last stage of steel processing in our production.

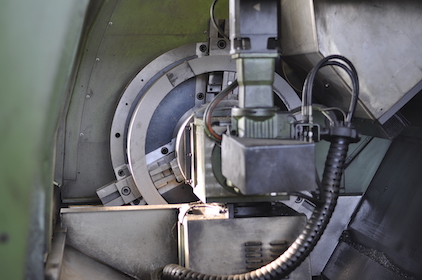

Based on the requirements of our customers, we also provide machining of produced forgings as the last stage of steel processing in our production. In 2008, we put into operation a new machine shop. There are both classic lathes and milling machines, as well as modern machine tools, such as the modern CNC machine tool Experturn 2000, which was put into operation in early 2016.

For smaller forgings, we provide their blasting using our own production equipment.

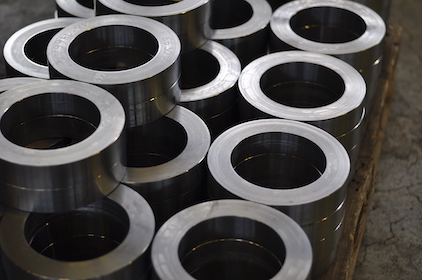

At present, we can offer our customers roughing or machining of forgings and steel semi-finished products to final dimensions. We perform these finishing operations for rings and discs, as well as for longitudinal forgings – shafts, axles, etc. The quality of machining of the processed parts is ensured by a thorough inspection by the employees at the output control of our company. On request, we are able to provide measurements using 3D tools.

We also provide the division of rings by cutting – a more productive replacement of lathe dividing.

WITH THIS TECHNOLOGY WE ARE ABLE TO DIVIDE RINGS WITH DIMENSIONS:

Max. outer ring diameter 2,500 mm

Min. inner ring diameter 300 mm

Max. ring wall thickness 150 mm

Min. split ring height 30 mm

Max. weight of split piece 1,300 kg

The production possibilities of the TRIANGOLO forge are determined by applied technologies. From this perspective, we offer die forgings, rolled rings, forged shafts and open die forgings. We also provide heat treatment of steel and metallurgical materials, machining and ultrasonic testing.

If you are interested in any other detailed information, you can contact us using the e-mail form below,

or through this contact information

© 2019 2HEADS s.r.o. Všechna práva vyhrazena.