Our company employs more than 100 highly qualified staff, who are daily involved in the production of high-quality products valued by our customers in the long term. The products are intended for sophisticated technologies and various projects almost all over the world. Our production premises cover an area of more than 30,000 m2. Our manufacturing equipment and technology can compare to the highest world standard in our industry. More than 70% of our production is for customers within the European Union based on the standards common to the region.

Our product portfolio can be divided into two sections. The first is supplies of forgings for the engineering industry (manufacturers of construction equipment, power equipment, production machines, bearings, etc.); the other is supplies of forgings for rail transport (tyres for trams, trains and metro, pressure rings, axles, etc.).

From the point of view of applied technologies, we produce rotary shaped die forgings (rings, flanges, etc.), open die forgings (bars, shafts, rings, plates, perforated discs, connecting rods, spindles, cubes, etc.); currently mostly seamless rolled rings (smooth rings, shaped rings, flanges, etc.). TRIANGOLO spol. s r.o. has a complete production chain, i.e. we ensure the realisation of the required product from the delivery and preparation of the material up to heat treatment, machining and quality control within

our own production capacities according to the customer’s request and documentation.

Since 1998, our company has been regularly certified according to ISO standards and holds the TÜV Management Service quality certificate.

Another significant milestone in the development of our company dates to 2017, when we became part of the investment group ANACOT CAPITAL. This significant step has allowed us to expand our production and supply potential by leveraging synergies across the Group. However, the most significant contribution is the start of a new era of development of the whole company, both in the area of trade and production, as well as in the area of human resources, innovation or modernisation of machinery and buildings.

The history of the forge dates back to 1955, when it was built and put into operation as part of the ZPS Hulín state enterprise. At that time, it was used primarily for the production of open die forgings in the field of engineering and military production.

Annually, we produce

Tires

We process

tonnes of steel

We have

years of experience

Triangolo s.r.o. is an industrial forge focused on custom production of small and medium-sized production series of forgings.

We process steel of all quality grades according to any standards based on customer requirements.

Project Number: 222222-2223-122-03-018

Programme: Development of information and communication technologies

Project completion: 2003

Within this project, we implemented a new information system NORIS in the company. This system covers the activities of all departments of the company, resulting in many advantages:

As seen from the above facts, we consider the implementation of the information system into our company to be successful.

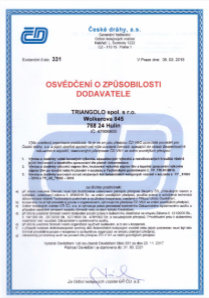

In recent years, the research and development has focused mainly on the development of technology for rolling shaped rings, especially semi-finished wheels for rail vehicles. As a result, the company is certified as an approved supplier of tram wheels, train tyres and axles for České dráhy (Czech Railways) and other companies operating not only on the Czech market but also on the world market. In this context, a series production of shaped tyres from the diameter of 450 mm to the diameter of 1,200 mm was commenced in the past years.

For these types of forgings, we naturally guarantee heat treatment, 100% control of dimensions and mechanical properties and ultrasonic tests, all complying with UIC standards, or other standards, and technical supplier standards in accordance with customer requirements.

The company TRIANGOLO spol. s r.o. launched physical realization of the project CZ.01.3.10 / 0.0 / 0.0 / 18_183 / 0016084 “Realization of austerity measures in TRIANGOLO spol. s r.o. ”. The subject of the project is the implementation of a set of measures that will lead to a reduction in the energy intensity of the forging company TRIANGOLO spol. s r.o. EU financial support is provided for the operation.

The company TRIANGOLO spol. s r.o. launched physical realization of the project CZ.01.3.10 / 0.0 / 0.0 / 18_183 / 0017581 “Realization of austerity measures in TRIANGOLO spol. s r.o., phase II. ”. The project is focused on the implementation of the next phase of a set of measures that will lead to a reduction in the energy intensity of the forging company TRIANGOLO spol. s r.o. specializing in the manufacture of forgings as well as the production of small and medium series. EU financial support is provided for the operation.

If you are interested in any other detailed information, you can contact us using the e-mail form below,

or through this contact information

© 2019 2HEADS s.r.o. Všechna práva vyhrazena.